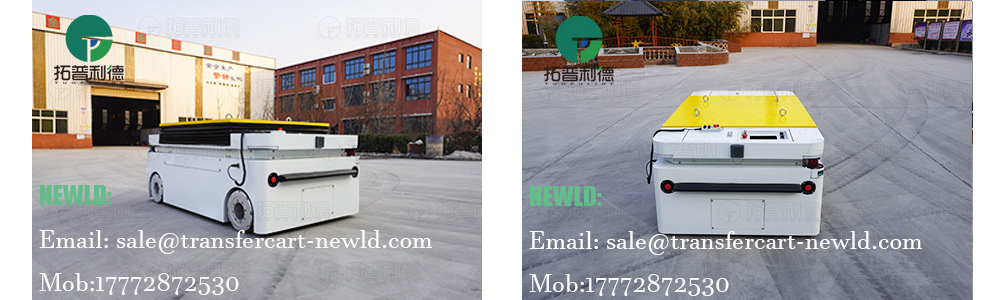

1.5 Tons Battery Drive Trackless AGV with Hydraulic Lifting Table

Production Challenges:

A certain automotive components factory production line faced significant difficulties with low material handling efficiency and severe space constraints. Traditional handling equipment required track installation, occupying valuable production space while imposing movement limitations. Frequent breakdowns in high temperature operating conditions severely disrupted production rhythms.

Solution:

The company introduced this trackless lithium battery AGV. Featuring a 2000×1200×800mm cast steel modular chassis and a mcanum wheel drive system, it achieves fully automated transfer throughout the entire process from the stamping line to the assembly area.

The core advantage lies in its modular design: a hydraulic lifting platform (adjustable range 0-250mm) perfectly accommodates irregularly shaped materials like circular or square items; the mcanum wheel steering system enables 360° on-the-spot rotation, requiring a minimum passage width of just 1.5 metres to navigate narrow workshop aisles effortlessly.

Intelligent control features include dual-mode switching between wired handheld and wireless remote operation. An LED display provides real-time monitoring of battery status and fault codes, while laser dead man stop (3-metre sensing range) and audible/visual warning lights form dual safety safeguards.

Applications:

The AGV boasts a heavy duty capacity of 1.5 tons, doubling efficiency compared to conventional forklifts. During material transfer tasks, hydraulic systems enable automated loading/unloading, reducing manual involvement and handling complexity, boosting single-shift output by 150%.

Its compact lithium battery delivers extended runtime, while shock-absorbing buffers ensure damage-free transport of precision components. Within six months of deployment, factory labour costs decreased by 65%, establishing it as critical equipment for multi-variety, small-batch flexible production lines.