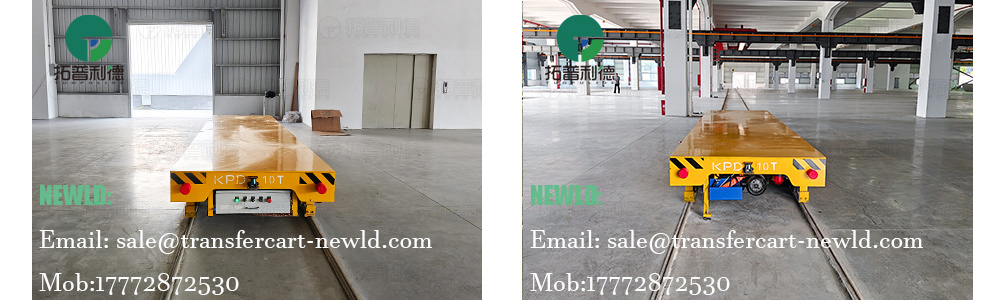

10 Tons Low Voltage Rail Transfer Cart for Construction Sites

Production Dilemma

On large-scale construction sites, the regional transport of heavy steel, prefabricated components, and construction materials often faces challenges such as long distances, heavy loads, and complex environments. Traditional equipment is susceptible to power supply limitations and poses safety risks.

Solution

The introduction of a 10 tons low voltage rail powered transfer cart, utilizing a 5000*1200*500mm box-girder frame and low voltage rail powered central power supply system, enables direct transport of steel from the processing area to the installation site. Low voltage rail power supply technology completely eliminates time and distance constraints, enabling continuous operation without stopping, providing a new option for transporting materials over 100 meters construction sites.

The transfer cart's advantage lies in its customized engineering design: a ground control cabinet + low-voltage rail + carbon brush + conductive post power supply design ensures a voltage drop of ≤5% over 100 meters of rail.

The insulated wheels, equipped with shock-absorbing devices, withstand impact from the gravel floor of the construction site, ensuring a stable operation of ±3mm/m. An automatic stop device (with a 3 meters sensing range) and an audible and visual alarm provide dual safety features. The lifting eye design facilitates quick crane loading and unloading, and the flat surface is suitable for transporting steel materials 6-12 meters long.

Applications

This transfer cart utilizes an intelligent coding control system for programmed transport, enabling continuous operation and meeting 24 hours construction requirements.

This reduces labor costs by 75% compared to traditional methods. It has become standard equipment for super-high-rise steel structure construction and is suitable for regional material transfer on construction sites, such as steel structure assembly, precast concrete panel delivery, and large formwork trolley coordination.

It enables efficient, continuous, and unmanned transport from the storage yard to the construction site, significantly improving material flow efficiency and reducing labor costs and operational risks.