Magnetic stripe navigation Battery AGV for Welding Workshop

Dilemma of Use

A large welding workshop routinely handles heavy welding equipment and materials in a high temperature working environment. Traditional handling methods are inefficient and unsafe.

Solution

This AGV, with its cast steel frame and custom work surface, boasts a stable structure and heavy duty capacity, easily carrying large amounts of welding materials. Its high temperature resistance ensures stable operation in high temperature workshop environments.

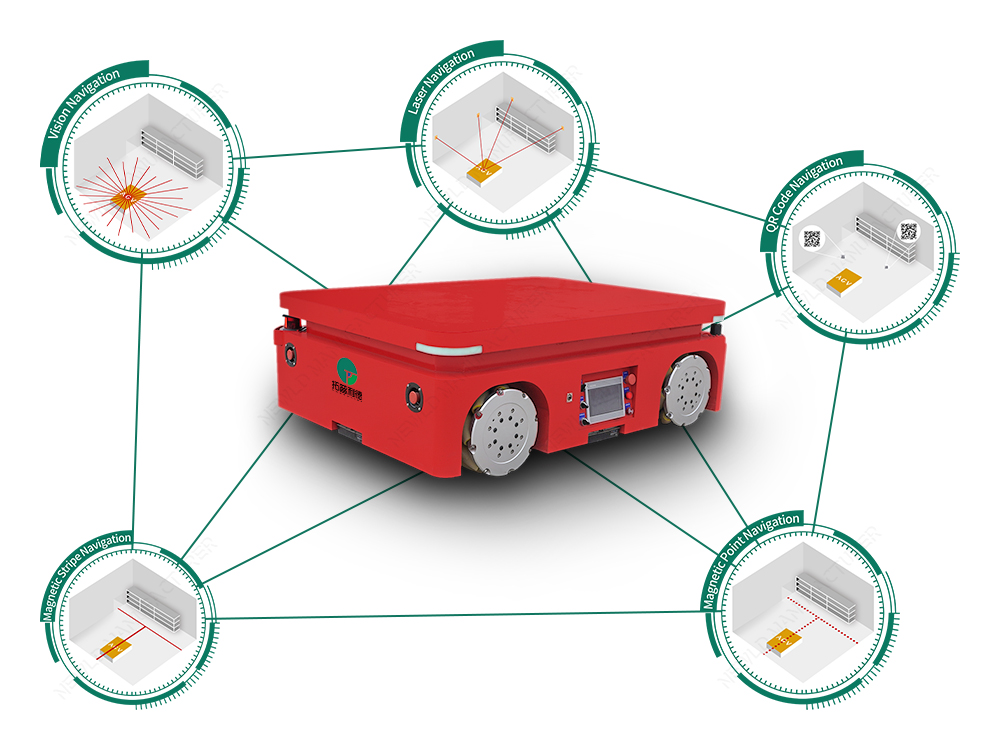

The AGV's trackless layout and magnetic navigation allow it to flexibly navigate between multiple welding,overcoming the flexibility limitations of traditional equipment.

Component

Its wireless remote control and intelligent coding control system allow for flexible movement throughout the workshop.

The mecanum design further enhances flexibility. A portable charging station and lithium battery ensure continuous power supply; an emergency stop button, laser dead man stop, and safety edge ensure the safety of both personnel and equipment;

a battery indicator provides an direct indication of battery level; and a three colors warning light indicates operating status.

A custom surface allows docking with a robotic arm, enabling automated operation, reducing human involvement and significantly improving work efficiency.

Application

This AGV achieves coordinated start and stop with the robotic arm through wireless remote control and an intelligent coding control system. Operators can easily dispatch the AGV carrying the robotic arm to different welding stations. LED displays provide real-time battery status information, and portable charging stations allow for on-the-go charging, eliminating battery life concerns.

The welding workshop has automated material flow, reducing station changeover time by 70%, eliminating the safety risks of manual handling, and significantly improving production line flexibility.