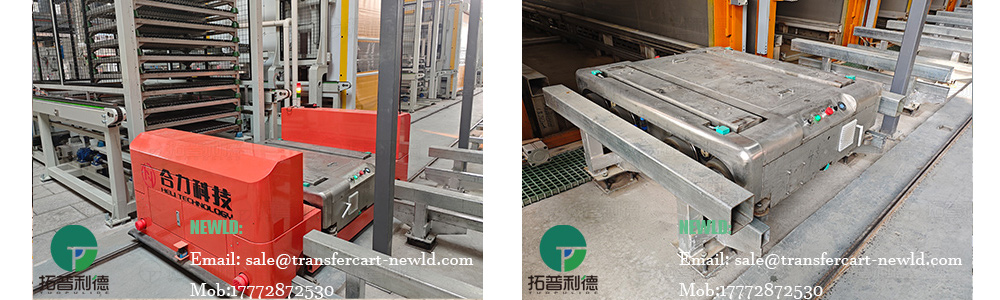

Customized Battery Powered RGV for Cross-Line Transport in Workshops

Production Challenge

In the workshop of a large machinery manufacturing company, the transport of heavy components between different production lines was a bottleneck to efficiency. Traditional transport equipment was limited by space constraints, lacked positioning accuracy, and was energy-intensive and complex to operate.

Solution

We customized this battery powered RGV system for this large manufacturing company. It utilizes high performance batteries, completely eliminating the limitations of ground cables. Combined with a wireless remote control and intelligent coding control system, it ensures the RGV can move freely throughout the workshop, perfectly adapting to changing production paths.

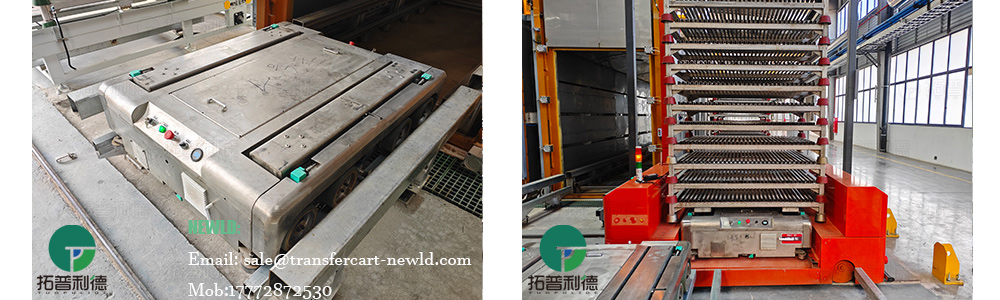

The vehicle body uses a robust cast steel frame to ensure heavy duty capacity. The lower transfer vehicle features a customized concave platform design, which can precisely engage or support the upper transfer vehicle, meeting the docking needs between specific production lines.

RGV equipped with three colors audible and visual warning lights and an emergency stop button, it ensures operational safety. Precise RGV positioning ensures accurate docking of components between different production line workstations. The RGV has high temperature resistance, enabling stable operation in production areas near high-temperature equipment, ensuring the equipment's environmental friendliness and high efficiency.

Application

By deploying the RGV (Rail Guided Vehicle) system, the customer successfully established a flexible and efficient material transport "bridge" between different production lines. The power display screen and LED screen provide real-time feedback on the operating status, and operators can easily schedule tasks via wireless remote control.

This greatly optimizes the workshop layout, reduces manual intervention, and truly achieves high efficiency and adaptability in the handling of parts in the production workshop.